Remembering a Picnic Classic: The Egg Toss

[March 4, 2025] With all the talk about egg shortages in the news lately, this photo from 1996 – when a dozen eggs averaged around $1.10 – caught our eye.

The egg toss was a popular and highly competitive picnic for many years. Not surprisingly, people who handle wood blocks all day are great egg catchers.

Bright Wood Unveils the Lengths We’ll Go to for 2x4 Customers at the 2024 Traders Market

[November 21, 2024] Thanks to all Bright Wood’s customers, suppliers, and friends in the wood products and building industries who dropped by our booth at the 2024 Traders Market in Phoenix, AZ.

It gave us a chance to:

We also heard some cringe-worthy stories from former (and now return) buyers who experimented with cheaper dimension lumber from overseas and paid for it with quality and mold issues.

Congratulations to this year’s winners of Bright Wood’s custom-made David Musty golf putters:

We’re already looking forward to the 2025 Traders Market. Until then, call Bright Wood at 541-475-2234 with your engineered dimension lumber questions and needs.

Art Frost: Redmond’s Go-To Fingerjoint Expert

[October 7, 2024] Art Frost is the Redmond site’s go-to guy for all things fingerjoint. He has worked all but five of his 51 years in the fingerjoint plant.

“I started in the cut plant on May 22, 1972,” Art said. “I was barely 18 years old, and my starting wage was $2.97.” It didn’t take Art long to decide that he wanted to work in the fingerjoint plant instead, but getting in was a problem. “Nobody moved, so it took me about five years to get in there, and then only because a whole new graveyard shift started in 1979. I’ve been here ever since and had no reason to go anywhere else.”

Art was promoted to swing shift lead on a Wednesday in 1983. “I had Wednesday, Thursday, and Friday to learn how to set fingerjointers,” Art said. “After that, I was on my own, and that is how I learned most of it.”

Art stayed on as the lead after Bright Wood purchased the Redmond site from Crown Pacific in 1997.

“Art is an extremely experienced fingerjoint setup person,” said Orville Wray, former Madras Plant 6 and Redmond Fingerjoint Plant Manager. “His knowledge of the fingerjoint process and products is priceless. His relentless pursuit of quality in machine setup, maintenance, and products is outstanding. Very few compare. He will dive into any issue and not give up until it’s been figured out.”

Thanks, Art. People like you are the reason customers seek out Bright Wood products. We wish you nothing but the best for retirement next spring.

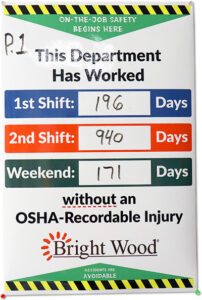

Redmond Day Shift Recognized for Safety Performance

[August 1, 2024] The Redmond site hosted a barbeque on July 31 for the day shift in recognition of finishing the second quarter without a recordable injury.

Darrell Matthews of the Maintenance Department served as barbeque master, grilling hamburgers and hot dogs for the day shift crew of 100.

Redmond’s manufacturing operations include cut, fingerjoint, lamination, profile wrapping, and veneer slicing plants. Their safety performance is a testament to the team’s vigilance in preventing unsafe acts and following procedures.

“Thanks to all the crew members for the increased focus on safety and use of safe work behaviors,” Redmond Safety Manager Laci Brown said. “You care, and it shows.”

Photos courtesy of Laci Brown and Emily Anders.

Midwest Team Thanked for Getting the Job Done SAfely

[June 10, 2024] Shout out to the Menomonie, WI operations for no recordable injuries since December 2022. According to George Loudermilk, Midwest Operations Manager, the 85-person crew’s 19-month run is down to: “Making sure people are aware of the hazards in their surroundings and the equipment they work with. We encourage everyone to watch out for each other and make safety equal to throughput and quality.”

“We want people to understand that Bright Wood’s safety policies and procedures are there to protect them and provide them with a safe work environment,” George said.

The busy Menomonie operations include a custom-sized extension jamb line, a paint line, and two warehouses. Every day, the team delivers components in the exact order they will be used to a nearby customer’s window assembly line. The Freitag location ships a truckload every 1-1/2 hours, averaging 50-plus outbound loads weekly. The Walton facility ships 45 truckloads weekly.

“We rolled out the STAR program (Safety Training Awareness and Responsibility) earlier this year,” Kim Miller, Menomonie Plant Manager, said. “Participation has been good, and people have become more aware of their surroundings.”

“I have heard a lot of positive comments about the high-vis vests from people on the floor along with truck drivers and vendors,” Kim said. “Everyone is very pleased with the focus on safety.”

All Menomonie team members received a $100 safety award bonus and a water bottle as a thank you and encouragement to keep up the good work.

Madras Plant 1 Swing Is a Safety STAR

[March 29, 2024] Well done to Madras Plant 1 swing shift for working 942 days (and counting) without a recordable injury as of March 29.

“We pay attention to what we do,” Sam Cabral, Swing Supervisor, said. “We use the STOP* and STAR** cards and all the available tools.”

“We do get a lot of STAR cards, and we are always pushing for more,” Miguel Sevilla, Swing Lead, said. “People are well aware of the dangers and watch out for one another.”

“It also helps that most have been here for a while, so they know what to do,” Miguel said. “When we first started, everybody and this plant were brand new, so it was harder.”

*STOP: Safety Training Observation Program

**STAR: Safety Training – Awareness and Responsibilities

Safety Is the Fashion Statement

[March 14, 2023] Thanks to all the Bright Wood people who quickly got on board with the new Personal Protective Equipment (PPE) policy requiring all associates and visitors to wear high-visibility attire while on company property. The only exceptions are offices and breakrooms.

High-vis clothing is one more tool for preventing workplace accidents and injuries. That pop of fluorescent orange and yellow makes people stand out in busy work zones and low-light conditions.

So, when you put on your high-vis gear before you get out of your car, know that you are making a difference.

P.S. Thanks to our models Jeremy Ross and Terrie Heflin of the Redmond Saw/Sand Plant. High fashion at its best.